From our independently developed DOC catalyst oxidation test and analysis platform to our proprietary DPF filter cleaning system, we have now successfully developed a new generation of testing equipment specifically designed for precise diagnosis of damage in DPF filter microporous structures.

Modern vehicles and machinery are equipped with PM sensors capable of detecting particulate matter escaping due to DPF filter damage. Once the sensor identifies such leaks, the control unit immediately intervenes in the equipment’s operation. This technical challenge has long plagued the supply chain of remanufactured diesel particulate filters.

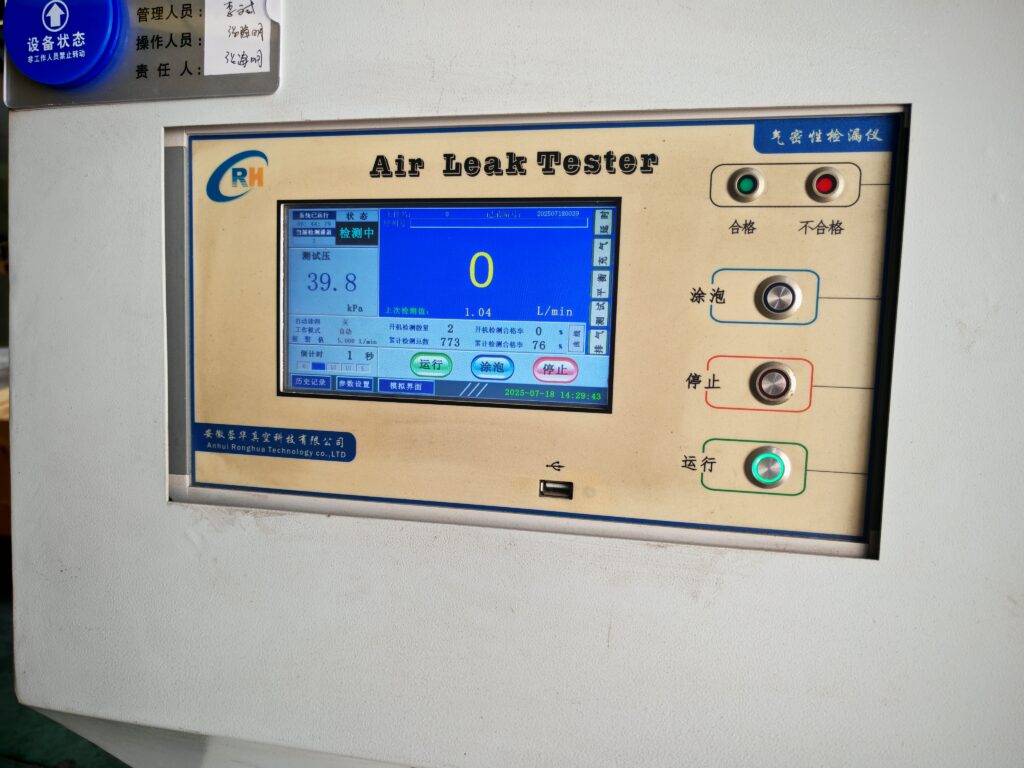

To ensure flawless filter cleaning processes and foolproof damage detection, we have once again taken the initiative, pioneering the development of our own DPF ceramic crack analysis technology. Currently, the prototype of this testing device has entered a critical phase of testing and validation, marking another strategic advancement in our precision diagnostics capabilities.