ASC (Ammonia Slip Catalyst)

ASC (Ammonia Slip Catalyst) is used in exhaust gas treatment, primarily in conjunction with SCR systems, to convert excess unreacted ammonia (NH₃) into nitrogen (N₂) and water (H₂O), preventing ammonia…

ASC (Ammonia Slip Catalyst) is used in exhaust gas treatment, primarily in conjunction with SCR systems, to convert excess unreacted ammonia (NH₃) into nitrogen (N₂) and water (H₂O), preventing ammonia…

Solutions: Regularly clean or replace DPF/SCR substrates. Inspect the exhaust system for blockages or damage. Avoid prolonged low-speed driving to ensure proper DPF regeneration. Summary: Excessive back pressure damages substrates,…

1. Substrate DamageCracking or Breakage: High temperature and pressure can cause ceramic substrates (e.g., DPF, SCR) to crack or break. Increased Clogging: High back pressure leads to particulate matter (PM)…

The single-core and multi-core designs of metal substrates are primarily based on exhaust flow requirements and spatial constraints. The single-core structure is simple and cost-effective, making it suitable for small-displacement…

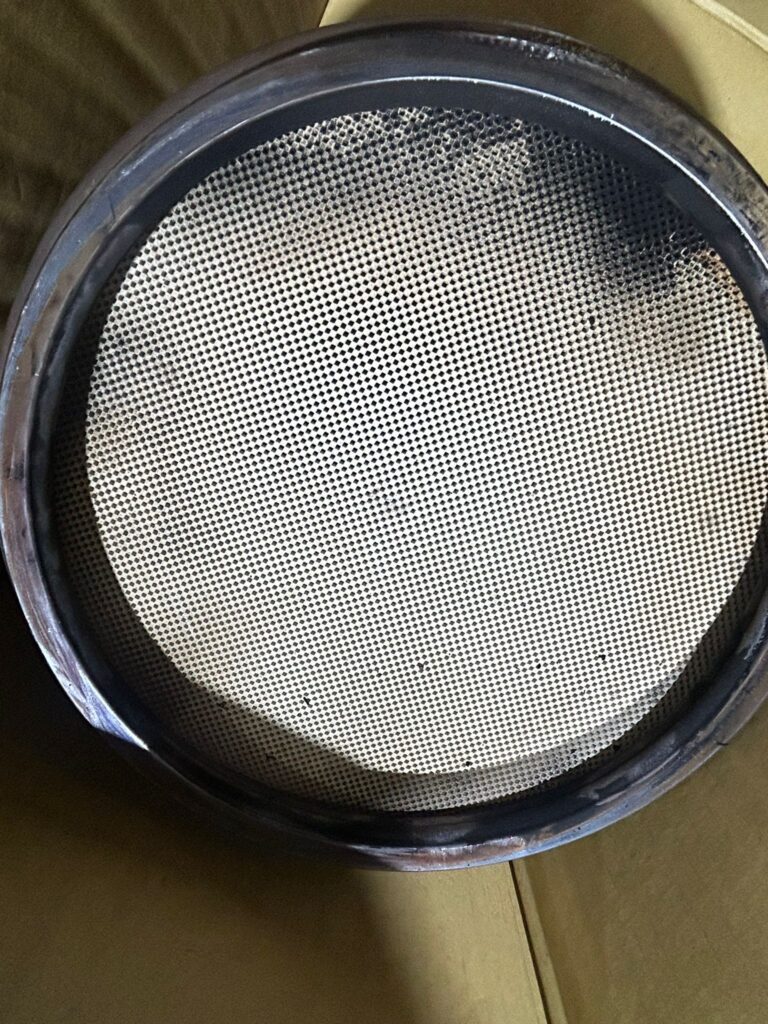

The metal substrate features a honeycomb structure made of heat-resistant alloys (e.g., FeCrAl) with ultra-thin walls (~0.05mm). As exhaust flows through, platinum/palladium catalysts convert CO and NOx into harmless gases…

The patterns on the two ends of a Diesel Particulate Filter (DPF) substrate are designed differently to optimize filtration performance, airflow distribution, and mechanical strength. Here are the key reasons:…

One Box Leak Test – Precision Sealing, Zero Leakage! Ensuring Safety & Efficiency for Exhaust Treatment Systems.

🏮 Happy Dragon Boat Festival! The aroma of zongzi spreads far and wide, and dragon boats race on the water~ 🛶🌿 #DragonBoatFestival #ChineseCulture

Trust Xichuang’s solutions to keep your emissions under control with unmatched quality.

Copyright 2024 © Xichuang. All right reserved. Powered by Easyceo.