Invisible exhaust, visible technology

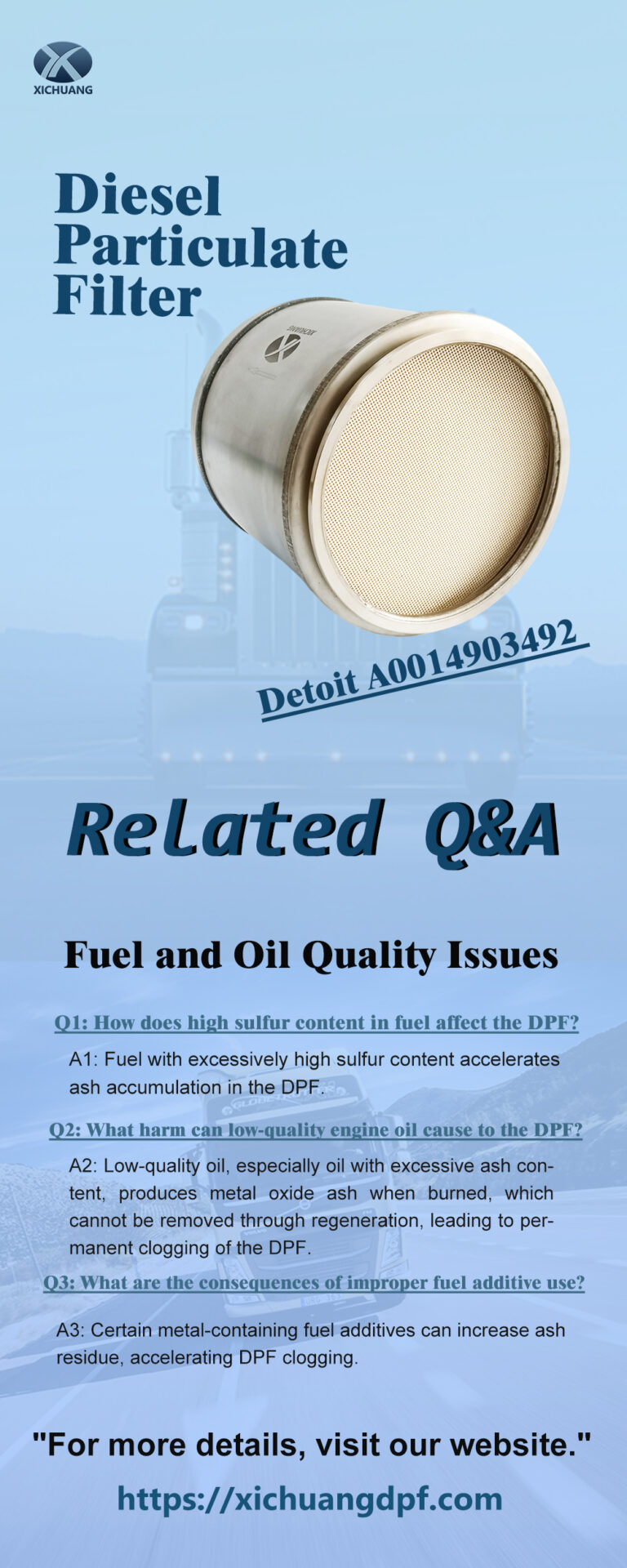

Failed emissions test? Headache! 😫Used car won’t sell for top dollar? Heartache!The root of the problem might just be your emissions system!Equipping your vehicle with OEM-grade emissions control assemblies from…