1. Substrate Damage

Cracking or Breakage: High temperature and pressure can cause ceramic substrates (e.g., DPF, SCR) to crack or break.

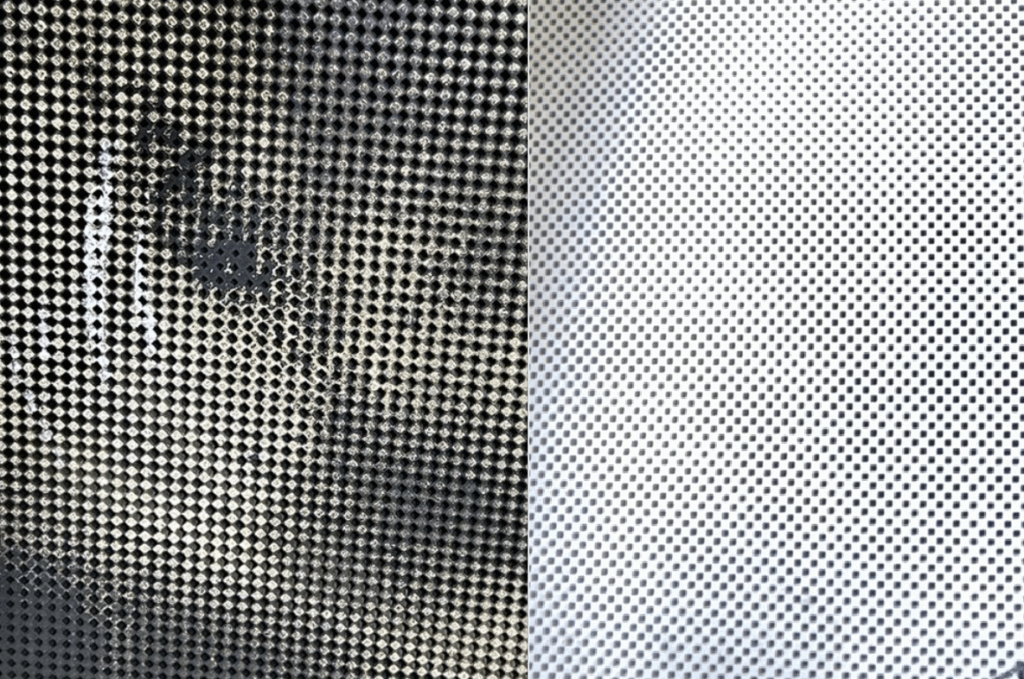

Increased Clogging: High back pressure leads to particulate matter (PM) buildup, further blocking the substrate.

2. Reduced Exhaust Treatment Efficiency

Catalyst Failure: Excessive heat can degrade the catalytic coating (e.g., SCR or DOC), reducing NOx and PM treatment efficiency.

DPF Regeneration Issues: Poor exhaust flow can cause incomplete regeneration, leaving soot unburned or even overheating and melting the substrate.

3. Engine Problems

Power Loss: Restricted exhaust flow worsens combustion, increasing fuel consumption and potentially triggering torque limitation.

Emission Non-Compliance: Incomplete combustion produces more pollutants, overloading the aftertreatment system.

4. Common Causes

1, DOC works poorly, resulting in ineffective regeneration, leading to DPF clogging and rapid increase in back pressure;

2,Engine combustion is poor, particles become larger and more numerous, leading to DPF clogging and increase in back pressure.

3,The DPF catalyst itself has excessive back pressure, leading to excessive initial back pressure;